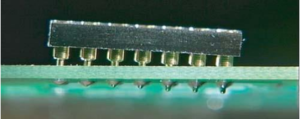

The factory for assembling electronic products mainly includes two production lines: SMT surface assembly and DIP plug-in assembly. SMT is the process of attaching electronic components onto a PCB circuit board through a device, then heating them in a furnace (usually referred to as a reflow soldering furnace), and fixing the components onto the PCB board through solder paste soldering; And DIP has some large connectors that cannot be connected to the PCB board by devices, so it needs to be plugged into the PCB board by humans or other automated devices.

In the production process of SMT and DIP, various factors can lead to some quality problems in the products, such as virtual soldering, which not only leads to unstable performance of the products, but also cannot be detected by subsequent ICT and FT tests, resulting in the flow of problematic products to the market, ultimately causing huge losses to the company’s brand and reputation. So how to avoid such problems, this article will carefully elaborate on it for everyone to popularize science

The reasons for SMT virtual soldering

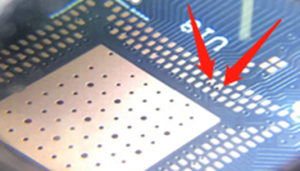

1.PCB design defects in solder pads

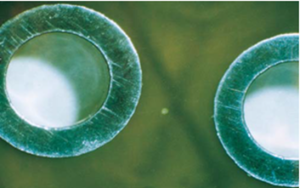

During the design process of some PCBs, due to limited space, through-holes can only be drilled on the solder pads. However, solder paste has fluidity and may seep into the holes, resulting in missing solder paste during reflow soldering. Therefore, insufficient solder on the pins can lead to virtual soldering.

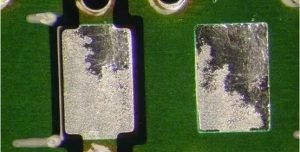

2.Surface oxidation of solder pads

After repainting tin on the oxidized solder pads, reflow soldering can lead to solder failure. Therefore, when the solder pads experience oxidation, they need to be dried first. If the oxidation is severe, they should be discarded.

3.Low reflow soldering temperature or insufficient time in the high-temperature zone

After the completion of SMT, when passing through the preheating and constant temperature zones of reflow soldering, the temperature is not enough, which leads to some components not having undergone hot melt soldering after entering the high-temperature reflow zone, resulting in insufficient soldering of the component pins and resulting in virtual soldering.

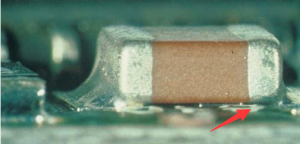

4.Too little solder paste brushing

When brushing solder paste, it may be due to small openings in the steel mesh and excessive pressure on the printing scraper, resulting in insufficient solder paste printing and rapid volatilization of reflow soldering solder paste, leading to virtual soldering.

5.High pin components

High pin components in SMT may experience deformation of the components, bending of the PCB board, or insufficient negative pressure in the SMT machine, resulting in uneven soldering and hot melt, leading to virtual soldering.

The reasons for DIP virtual soldering

1.PCB plugin hole design defect

The plug-in holes of the PCB have a tolerance of ± 0.075mm. The packaging holes of the PCB are larger than the pins of the physical device, causing the device to loosen, resulting in insufficient soldering and quality problems such as virtual soldering or empty soldering.

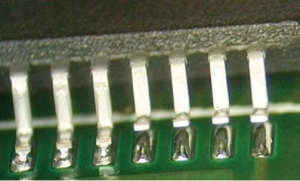

2.Solder pads and hole oxidation

Unclean, oxidized, or contaminated with dirt, grease, sweat, and other contaminants on PCB pads can lead to poor solderability or even non solderability, resulting in virtual or empty soldering.

3.PCB board and device quality factors

The solderability of the purchased PCB boards, components, etc. is not up to standard, and strict acceptance tests have not been conducted. There are quality issues such as false soldering during assembly.

4.Expired PCB boards and components

The purchased PCB boards and components have a long inventory period and are affected by the warehouse environment, such as temperature and humidity differences or corrosive gases, resulting in virtual soldering and other phenomena during welding.

5.Wave soldering equipment factors

The high temperature in the wave soldering furnace leads to accelerated oxidation of the solder material and the surface of the base material, resulting in a decrease in the adhesion of the surface to the liquid solder material. In addition, the high temperature also corrodes the rough surface of the base material, causing a decrease in capillary action and a decrease in fluidity, leading to virtual soldering.

DYC have 18 years of experience, and we will control and detect these issues on a daily basis. After careful consideration at each stage, the final product will be OK. Please rest assured to cooperate with us.