During SMT processing, electrostatic discharge can cause damage or failure to electronic components. With the improvement of IC integration and the gradual reduction of components, the impact of electrostatic discharge becomes increasingly severe.

According to statistics, static electricity accounts for 8% to 33% of the factors that lead to the failure of electronic products, and the annual loss of electronic products caused by static electricity can reach billions of dollars.

Therefore, implementing electrostatic protection measures is very important in SMT production. This article will provide a detailed introduction to how to take effective electrostatic protection measures from the generation of static electricity to the protection of components and scenes.

How is static electricity generated?

ESD (Electro-Static Discharge),ESD is a physical phenomenon that refers to the charge transfer caused by objects with different electrostatic potentials approaching or directly contacting each other. In the process of charge transfer, there is a flow of charges that transfers enough electricity to offset the voltage.

For example, when walking on the floor mat in winter, one may feel an electric shock; When touching the handle in winter, one may also feel electrified; The crackling sound heard while putting on clothes, and so on.

These insignificant static electricity phenomena in daily life have a significant impact on electronic components and circuit boards, such as the possibility of electrostatic breakdown that can cause component damage or failure, thereby affecting electronic products. So what are the common static electricity in SMT production?

Common Principles of Static Electricity Generation?

- Friction electrification

When two different materials rub against each other, one of them carries an electric charge, forming static electricity.

- Induction electrification

The phenomenon of charge redistribution occurs in objects under the action of an electrostatic field. When a charged object approaches a non charged object, a potential difference is formed between the two, which causes the charge to move on the non charged object, resulting in the generation of static charges on the non charged object.

- Capacitive electrification

Due to the change in capacitance of a charged body when it approaches or separates from another object, the electrostatic potential on the charged body will change, forming static electricity.

- Static electricity in daily life:

1.Walking on the carpet can generate static electricity of 1.5KV to 35KV;

2.When walking on vinyl ester flooring, static electricity of 250V~12KV can be generated;

3.Indoor buttocks can generate static electricity above 1.8KV when rubbed against a chair;

4.When getting up from the sofa, the static electricity in the human body can reach up to 10KV;

5.The static voltage when taking off synthetic clothes can reach tens of thousands of volts.

Electronic components should pay attention to anti-static measures:

Electronic components that are sensitive to static electricity generally have anti-static labels. When encountering components with these labels during the production process, special attention should be paid to anti-static issues.

Semiconductor integrated circuits have taken protective measures against electrostatic failure in their design, providing protection for sensitive components against electrostatic discharge below 2000V. At the same time, protective resistors and embedded diodes can be added to the peripheral design of the circuit to enhance its anti-static ability.

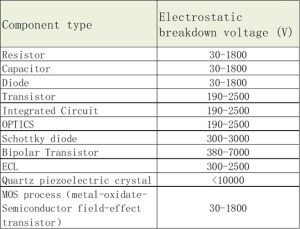

Electronic components sensitive to static electricity:

[Note] These values are for reference only

Damage forms of electronic components:

- Completely lose function

1) Manifested as severe deterioration of device electrical parameters and loss of original functionality;

2) About 10% of the components are damaged by static electricity.

- Intermittent loss of function

1) The performance is that various electrical parameters of the device or product are still qualified, but its service life will be greatly shortened, reliability will deteriorate, and it may completely fail in a subsequent damage;

2) About 90% of the components are damaged by static electricity.

Common scenarios of electrostatic damage:

01:Placement of components

When placing components on the SMT board, due to the presence of static electricity, the components may slip or deform from the placement position, resulting in defects or malfunctions.

02:Accumulation of electrostatic charges

Due to the metal casing and grounding device of SMT equipment, static electricity will accumulate. If the static electricity is not released in a timely manner, it will cause damage to the components.

03:Pollution damage

Static charges can adsorb impurities such as dust and oil, causing surface contamination of components or circuit boards, thereby affecting their normal operation.

04:Adsorption damage

During transportation, storage, or assembly, static charges can adsorb onto components or other components, causing them to malfunction or be damaged.

Basic principles of electrostatic protection:

- Use or install static sensitive components in static safety areas.

- Use static shielding containers to transport and store static sensitive components or circuit boards.

- Regularly check if the installed electrostatic protection system is operating properly.

- Ensure that suppliers understand and adhere to the above three principles.

Electrostatic protection steps:

1.Avoid placing static sensitive components and circuit boards together with plastic products or tools.

2.Ensure that the floor and table mats in the work area have sufficient conductivity, preferably using conductive rubber tabletops or sticking conductive tape to the four sides of the table.

3.Regularly check if the grounding system is in good condition, and the grounding cable must be correctly connected to the busbar.

4.When using electronic tools or instruments, it is necessary to ensure that the tools or instruments used comply with electrostatic protection requirements.

5.The use of plastic bags, foam boxes and other packaging materials is restricted. If it is necessary to use them, it is also necessary to ensure that the packaging materials are electrically treated or the packaging boxes made of metal materials are used.

6.Wear anti-static clothing, shoes, use anti-static tools, gloves, and anti-static wristbands.

7.Hire professionals who have received training in electrostatic protection to ensure that anti-static measures are implemented correctly.

8.Regularly conduct static electricity protection inspections and tests to ensure the effectiveness of anti-static measures.

9.Employees and guests who are not wearing wristbands are prohibited from approaching the electrostatic protection workstation. Once any violations are found, they should be immediately stopped and reported to their superiors.

10.If any problems or defects are found in the electrostatic protection system, they should be immediately reported to the superior or the person in charge of electrostatic protection, and measures should be taken in a timely manner for improvement and handling to ensure the effectiveness of the electrostatic protection system.

Static electricity protection is highly valued in our DYC, and every employee is required to take proper precautions. This has enabled us to use effective methods in our experience to ensure the integrity of our PCBA products.

Hand over production to us and give you the best!