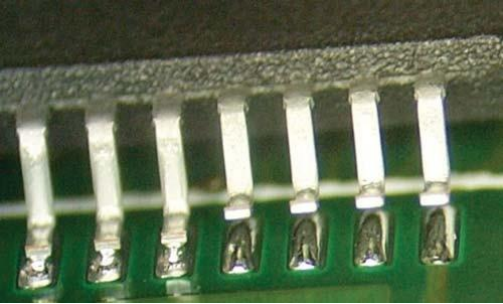

How to avoid SMT virtual soldering problem

The factory for assembling electronic products mainly includes two production lines: SMT surface assembly and DIP plug-in assembly. SMT is the process of attaching electronic components onto a PCB circuit board through a device, then heating them in a furnace (usually referred to as a reflow soldering furnace), and fixing the components onto the PCB board through solder paste soldering; And DIP has some large connectors that cannot be connected to the PCB board by devices, so it needs to be plugged into the PCB board by humans or other automated devices. In the production process of SMT and DIP, various factors can lead to some quality problems in the products, […]