How Do Circuit Boards Work: A Comprehensive Guide to the Heart of Electronics

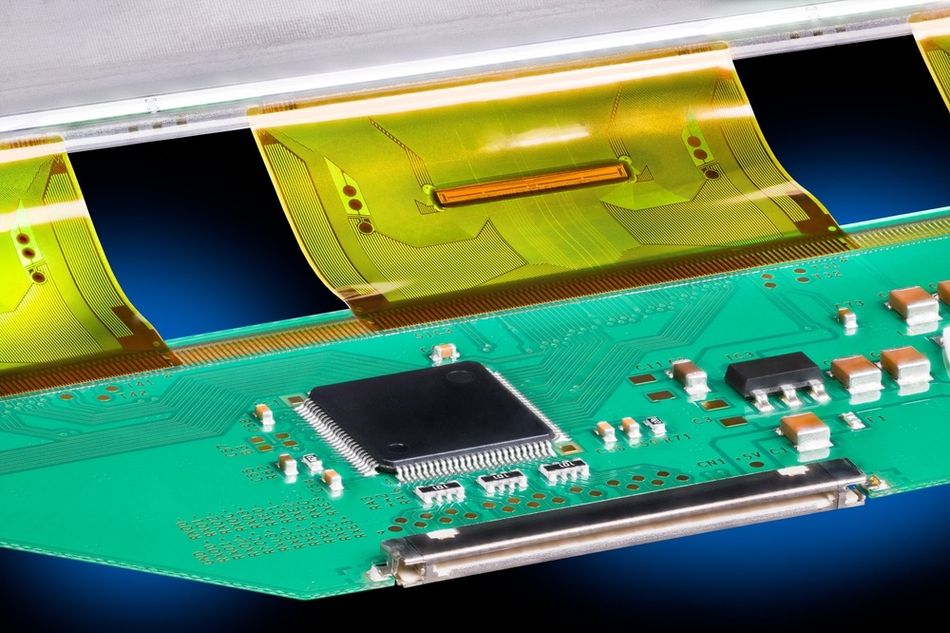

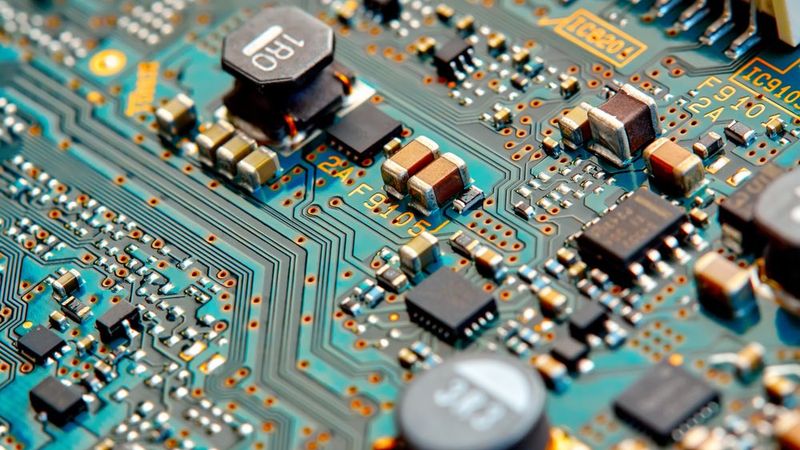

From Blueprint to Functionality: Navigating the Intricacies of Circuit Boards – Manufacturing, Mechanics, and Troubleshooting Demystified A typical circuit board with components and wiring traces What are Circuit Boards? A circuit board is a fundamental component in electronics. It’s the backbone of most electronic devices, providing a platform for the arrangement and interconnection of electronic […]

Rigid PCB: Complete Engineering Guide & Advanced Design Techniques

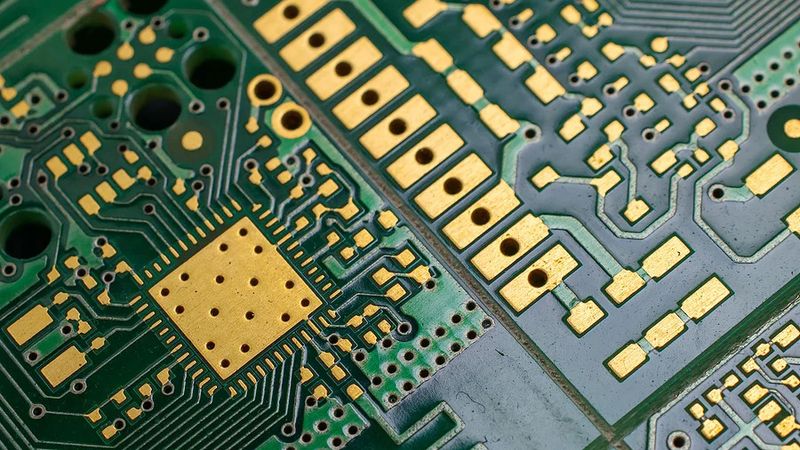

Understanding the need for Rigid PCB technology, capturing its manufacturing process and applications, and the innovations it has brought in modern electronics design and industrial manufacturing. Rigid PCB are integral part of modern consumer electronics Introduction In the world of modern electronics, the Printed Circuit Board (PCB) serves as the foundational backbone, connecting disparate components […]

HASL vs ENIG: Choosing the Right PCB Surface Finish

This article aims to provide a comparative analysis of HASL vs ENIG, providing valuable insights to aid in making informed decisions for PCB design and manufacturing HASL vs ENIG Surface Finish Introduction In PCB manufacturing, surface finishes play a crucial role in protecting exposed copper traces and ensuring optimal performance. These finishes act as a […]

Understanding the ENIG Finish: A Comprehensive Guide

This article delves into the basics of ENIG finish, its application process, advantages and disadvantages, challenges, and comparative analysis with other finishes. Printed Circuit Board with Electroless Nickel Immersion Gold Introduction In the world of electronics, The ENIG finish, or Electroless Nickel Immersion Gold, is a critical aspect, particularly in Printed Circuit Board (PCB) manufacturing. […]

Types of Printed Circuit Boards: A Comprehensive Guide

This article delves into the various types of printed circuit boards, their fundamental concepts, structures, manufacturing processes, and advanced PCB technologies, highlighting their advantages, limitations, and typical applications. Types of Printed Circuit Boards Introduction Printed circuit boards (PCBs) are the foundation of modern electronics, providing a reliable method of connecting electronic components. These boards consist […]

What are Circuit Boards Made Of? An Extensive Guide to Materials and Manufacturing Processes

Unveiling the Art and Science Behind Circuit Boards – Copper Etching to Silkscreens, a Comprehensive Guide to Elements, Manufacturing Processes, and Multilayered Varieties in Electronic Circuit Boards What are Circuit Boards? Circuit boards, also known as printed circuit boards (PCBs), are the backbone of virtually all modern electronic devices. From smartphones and computers to advanced medical equipment […]

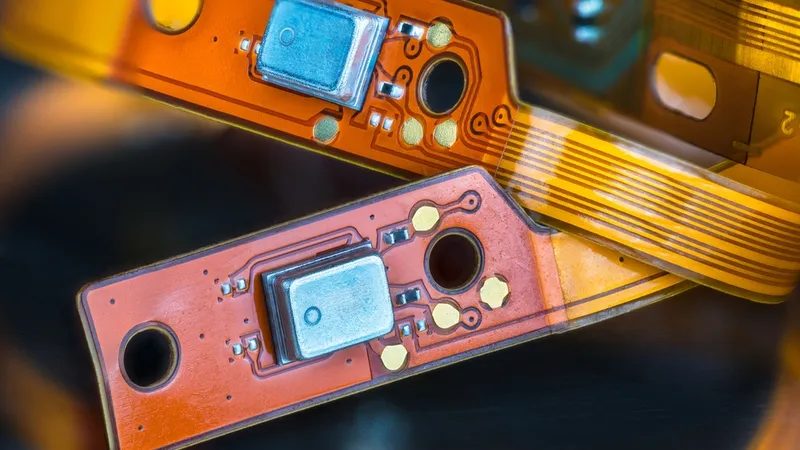

Flexible PCBs in Modern Engineering

This article delves into the innovative world of flexible printed circuit boards, uncovering their design, advancements, and transformative role in modern engineering applications. PCB or small components on flexible ribbon cables Introduction Flexible printed circuit boards (PCBs) have revolutionized electronic circuit design with their ability to conform to various shapes and spaces, unlike traditional rigid-flex […]

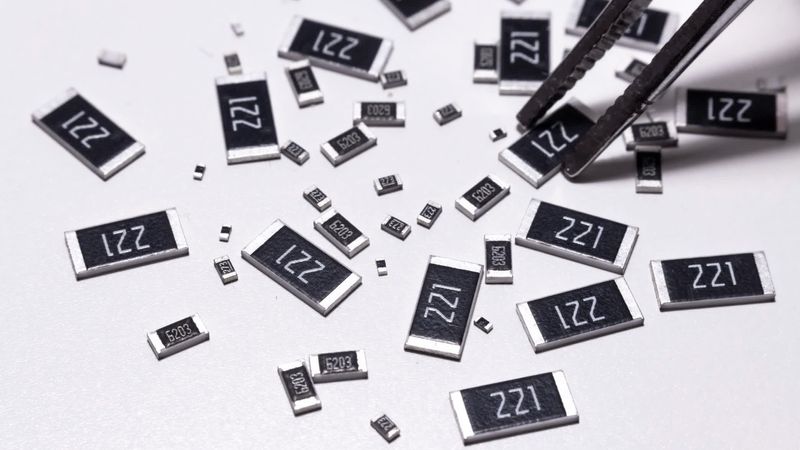

SMD Resistor Sizes: A Comprehensive Guide for Engineers

Learn about the various sizes of SMD resistors, their impact on electronic circuit design, and the latest technological advancements in SMD Resistor Technology. This guide discusses practical insights for engineering professionals looking to optimize their designs with precise resistor sizes. Introduction Surface-Mount Device (SMD) resistors are critical components in modern electronic circuits, offering compactness and […]