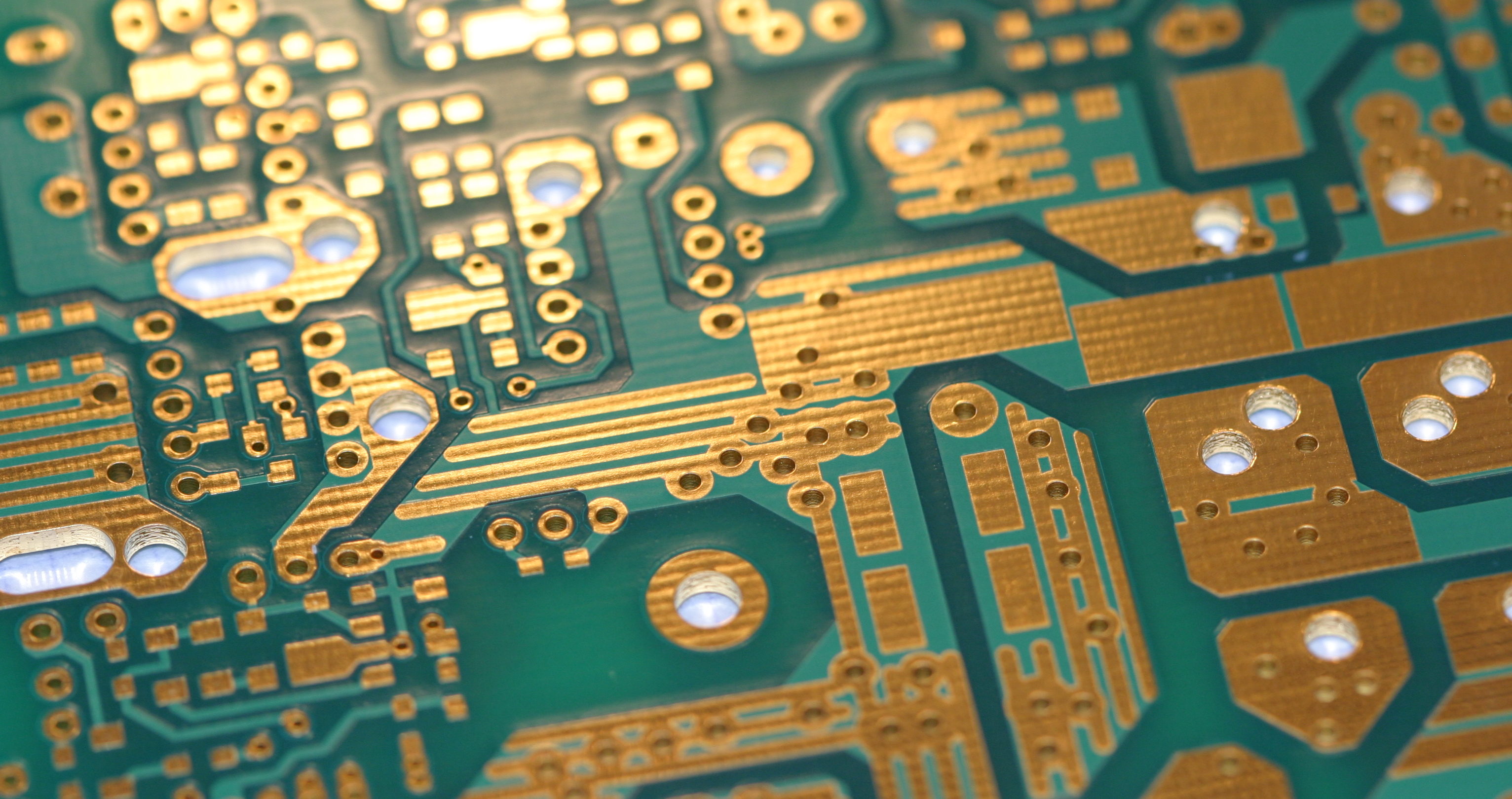

Choosing the appropriate board is crucial in the PCB manufacturing process. Here are some common PCB boards and their characteristics introduced:

1. **FR-4**: This is the most common type of PCB material, composed of woven glass fibers soaked in epoxy resin. It offers excellent electrical insulation and mechanical strength, making it suitable for a wide range of applications. FR-4 is known for its versatility and reliability, and it is cost-effective.

2. **Polyimide (PI)**: Used for flexible PCBs, polyimide provides exceptional performance in harsh environments and high-temperature conditions. It is dimensionally stable during thermal cycling, making it ideal for multi-layer PCB constructions.

3. **Teflon**: Known for its excellent dielectric properties and minimal resistance, Teflon is used in high-speed, high-frequency circuitry applications. It is relatively expensive but offers high performance.

4. **CEM Series**: These laminates are typically composed of woven glass fabric surfaces and glass cores combined with epoxy resin. They are known for their high-temperature tolerance and are suitable for high-density applications.

5. **Flexible Laminates**: Materials like polyester, liquid crystal polymer, and polyethylene naphthalate (PEN) are used for flexible PCBs. These allow the circuitry to bend or fold without sacrificing electrical stability.

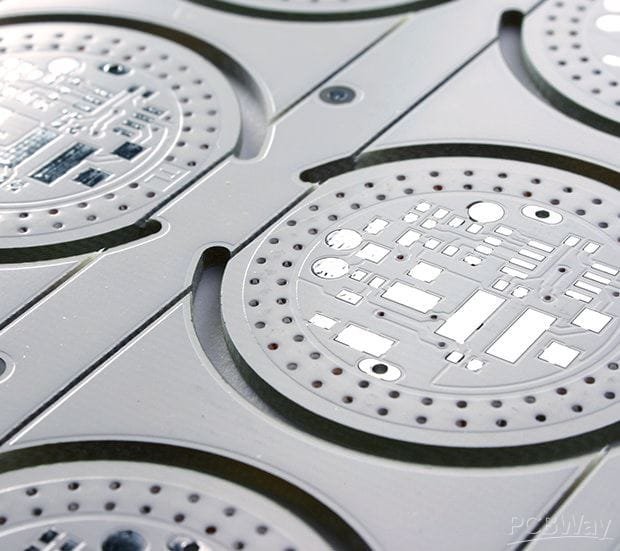

6. **Metal Core PCBs**: These utilize a base metal material for heat distribution, with a dielectric polymer layer for high thermal conductivity and low thermal resistance. They are used in applications like street lighting and other heat-sensitive environments.

7. **High-Performance FR-4**: Ideal for multi-layered PCBs, this laminate has a higher glass transition temperature (Tg), providing better reliability and low dielectric properties for high-frequency circuits.

8. **High Tg Epoxy**: Suitable for multilayer PCBs, this laminate has a higher Tg, indicating better resistance to heat, moisture, and chemicals, as well as improved stability.

9. **BT Epoxy**: Best for lead-free PCBs, this laminate offers outstanding thermal, mechanical, and electrical properties, maintaining bond strength at high temperatures.

10. **Copper Clad (CCL)**: Made with glass fiber or wood pulp paper as the reinforcing material, this laminate is used in high-voltage circuits and has various performance requirements.

Each material has its own set of properties that make it suitable for specific applications, and the choice of material can affect the PCB’s performance, cost, and reliability. When designing a PCB, it’s important to consider the electrical, mechanical, and thermal requirements of the application to select the most appropriate substrate material.