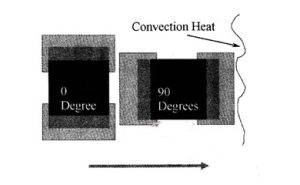

On the test board, the components are placed in two directions, 0 ° and 90 °. Determine whether component orientation (0 ° and 90 °) significantly affects the yield of assembly by analyzing paired samples. The 0 ° direction indicates that both ends of the component pass through the furnace simultaneously, while the 90 ° direction indicates that one end of the component passes through the furnace before the other end, as shown in Figure 1.Direction of components

The hypothesis verified is:

- The virtual assumption is that z=0- there is no statistically significant difference in the number of assembly defects between the 0 ° and 90 ° directions.

- Furthermore, assuming that Z ≠ 0- there is a significant statistical difference in the number of assembly defects between the 0 ° and 90 ° directions.

For the air reflow soldering process of self-cleaning solder paste, the P-value (confidence level) is 0.5165. Due to the high P-value, we cannot reject the virtual hypothesis. Therefore, when using wash free solder paste for reflow soldering in air, there is no significant difference in the direction of the components on the assembly yield. That is to say, due to the low activity of the wash free soldering flux, there is no increased risk of standing a monument (open solder joint) during reflow soldering in the air.

The P-value obtained by reflow soldering with water-soluble solder paste in air is 0.001959. Due to the low P-value, the virtual hypothesis was rejected. Compared to the washable solder paste, for components in the 90 ° direction, the increase in flux activity in water-soluble solder paste results in a significant increase in standing (open solder joint) defects.

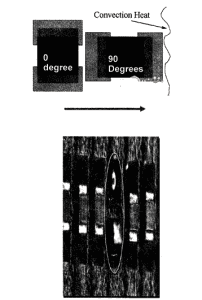

The P value obtained by refluxing soldering with washable solder paste in nitrogen is 0.000 002. Due to the low P-value, the virtual hypothesis was once again rejected. Due to the use of nitrogen (oxygen concentration below 50 ppm), there is an increased opportunity for components to produce monument defects in the 90 ° direction. According to the inspection of the discovered monument defects, the vast majority of open solder joints appear at the end of the components that return later, as shown in Figures 2 and 3.

Figure 2 shows that the 90 ° direction of the component enters the reflow furnace. Figure 3 shows that the soldering end of the later reflow is open circuited in the 90 ° direction of the component。